OVERVIEW

TAIKO® started producing bleaching clays in 1993. The clay business has proven to be a good fit for the Group. Over the years, TAIKO® has developed comprehensive understanding of the market, which drives the Group’s transition from a small domestic producer to a major global supplier.

This strong association with the edible oil industry coupled with our steadfast focus on R&D have given us ample wealth of knowledge and experience to better serve our customers. TAIKO® has a team of dedicated geologists identifying and extracting raw clay which fulfills compliance to strict global regulations and specifications. We operate an extensive global supply network which is supported by strategically located distribution hubs.

Our continuous investment in process improvement and capacity expansion enables us to stay ahead with the growth in the oils and fats industry.

Today, TAIKO® activated bleaching clays are present in Asia, Europe, Oceania and Africa.

OUR MISSION

WHY TAIKO® CLAY?

- CATERS TO A WIDE SPECTRUM OF OIL FEEDSTOCK AND QUALITY

- SMOOTH REFINING OPERATION WITH HIGH TOTAL VALUE

- FULL TRACEABILITY WITH INTERNATIONAL COMPLIANCE

- DEDICATED TECHNICAL SUPPORT AND SOLUTION PROVIDER

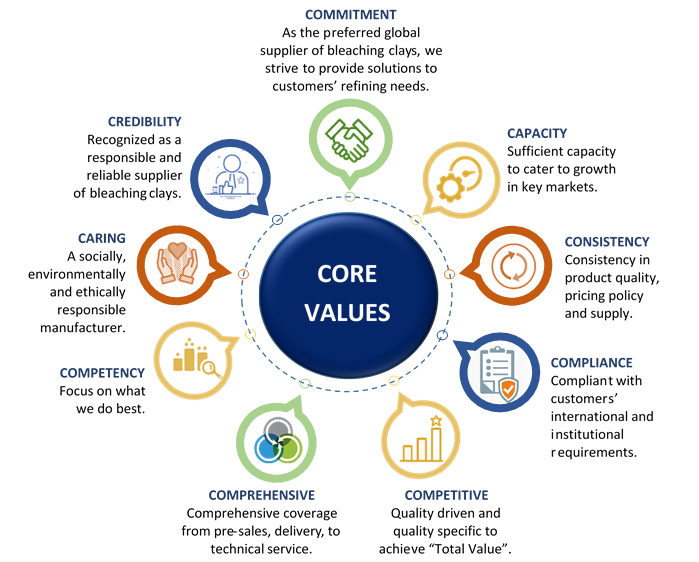

CORE VALUES

Recognized as a responsible and reliable manufacturer and supplier of bleaching clays to the world’s major edible oil refiners. We are in full compliance with all international regulatory bodies.

PRODUCT

Overview

Our Group’s core product is Bleaching Earth, a highly effective adsorbent essential in the refining process for the purification and decolourisation of edible and non-edible oils, fats, tallow, petroleum jelly, paraffin oil and waxes.

Taiko’s range of Bleaching Earth are manufactured and sold under the trademark.

Bleaching Earth is world renowned for its consistency in quality, performance and efficiency in meeting even the most demanding refining requirements. Our portfolio of international clients constitutes some of the largest and most reputable edible oil businesses in the world.

Best of all, Taiko Bleaching Earth offers our customers the lowest total cost of ownership, because it works harder and more effectively for you.

Product Name

Chemical Name

TAIKO® Bleaching Earth

Bentonite, acid activated

CAS Number: 70131-50-9

EINECS Number: 274-324-8

Synonym: Activated Bleaching Earth

Physical & Chemical Properties

AppearanceFree flowing powder |

OdourOdourless |

pHMildly acidic in suspension |

Boiling PointN/A |

Melting PointN/A |

Flash PointN/A |

FlammabilityNot flammable |

Explosive PropertiesNon-explosive |

Oxidizing PropertiesNone |

Vapour PressureN/A |

Relative Density350 – 1000 |

SolubilityNegligible solubility in water, solvents or oil |

Chemical Composition

| SiO2 | 55 – 80 |

| Al2O3 | 5 – 20 |

| Fe2O3 | 2 – 10 |

| MgO | 0 – 8 |

| CaO | 0 – 5 |

| Na2O | 0 – 2 |

| K2O | 0 – 2 |

Notes:

Analysis may vary with bleaching earth source and is quoted as % dry weight.

Elements present in the bleaching earth have been expressed as their oxides.

SUSTAINABILITY

Flexible Solutions For Your Needs And Requirements

In order to stay ahead of the ever rising global demand while addressing stringent international compliances and food safety regulations, TAIKO® has continued to strive for improvement in quality excellence and product reliability through extensive research and development.

Having control over our supply chain – from raw clay mining to finished product distribution – and adaptive technical support enable us to develop effective mitigation measures and strategies to the major challenges in the industry.

TAIKO® views sustainability as an integral part of its business operations and is consistently seeking ways to implement environmental, social and civil best practices.

TAIKO® fit-for-purpose acid activated bleaching clay would have a grade for your refining needs. Based on your refining activity, our dedicated sales and technical support team will be able to provide the best solution for your scope of application.

Challenges Ahead

FOOD SAFETY & QUALITY

Growing health awareness drives concern regarding 3-MCPDE and GE.

Possible causes of cancer and genotoxicity upon digestion.

ENVIRONMENTAL SUSTAINABILITY

Having to comply with increasingly stringent environmental regulations to build a sustainable future.

Committed to implementing responsible sourcing and adopt more sustainable practices.

MANAGING COST

Refiners strive for ways to improve productivity and efficiency to enhance competitiveness.

TAIKO® delivers total value through product quality and certified solutions.

FIT FOR PURPOSES

Selection of bleaching earth is dependent on the type of edible oil refined, quality of the edible oil feedstock, the refining process and the desired quality of the refined oil. Correct selection of fit for purpose bleaching earth also plays a role in maximizing a refinery’s full potential capabilities. In addition to working with customers, we also listen and learn from process technology suppliers on the developments in their respective areas of expertise. This allows us to develop new products that work seamlessly with new process technology.

Our team of product application specialists are competently trained and experienced to assist our customers in the selection of fit for purpose Taiko bleaching earth.

Edible Oils

Edible Oils, which have triglyceride composition rich in monounsaturated and polyunsaturated fatty acids, make the oils extremely sensitive to oxidate damage and quality deterioration. The oxidation process eventually leads to colour darkening and off-flavour, which in an advanced stage will cause the oil to go rancid, causing an unpleasant odour/flavour. In view of refined edible oils and fats forming an important part of everyone’s diet, bleaching earth are utilized to adsorb various impurities from oils and fats. This imparts better stability to the oils and fats, which means that they have longer shelf life. Most important of all, we believe the quality does not stop at your factory but goes all the way to the dining table.

Soaps

Apart from edible uses, oils and fats are employed in a multitude of other non-edible applications. Soaps are probably the most important of these non-edible applications and bleaching earth of the highest standard are necessary to ensure that the oil base meets the stringent requirements in the production of cosmetic and toilet soap.

Non-Edible Oils

There are many applications where bleaching earth are utilised to refine oils, fats and waxes for non-edible purposes. Among them are the utilization of highly refined linseed and soya bean oils in the formulation of high-quality surface coatings. Refined waxes are ingredients in some of the best-known and durable car polishes. Refined white petroleum jelly and white oil (liquid paraffin) are used in the manufacturing of cosmetics, personal care and pharmaceutical products. High active bleaching earth are also utilised in the refining of caster oil for industrial applications.

Biofuel

Increasing environmental awareness has been one of the driving forces towards production of renewable fuels, such as methyl ester. Bleaching earth are used widely in pre-treatment and post-treatment of methyl esters to meet stringent international biodiesel quality specifications. The bleaching earth mainly function as an adsorption agent in soap removal.

DELIVERY OPTIONS

Polypropylene bags also available

Weight dependent on product density

For road deliveries in selected locations

SUPPLY CHAIN

Having direct control over our supply chain improves our management of product consistency. We have control over our supply chain starting from our mining operations until product distribution. Besides managing consistency of our raw materials, our investment in raw materials also assures us sustainable supply of raw materials.

Continuous investment in process improvement and capacity expansion enables us to consistently meet our customers’ expectations and prepares us to anticipate the growth in the vegetable oils and fats industry.

Compliance with statutory and civil safety, health and safety regulations at all our manufacturing plants assure uninterrupted production and supply of Taiko bleaching earth to our customers.

Taiko bleaching earth deliveries in bulk are transported by competent drivers trained in the responsible carriage and handling of bleaching earth. Our product traceability system tracks products that are packed in both bags and in bulk. The product traceability lot number appears in the certificate of analysis that accompanies each product delivery.

We have sales teams in all our core markets. In addition to our own sales teams, we work with a network of highly professional distributors and agents in our overseas markets. Our sales efforts are supported by a team of product specialists and another team of product application specialists. While the product specialist is an expert in the science of bleaching earth, the product application specialist assists in correct selection of Taiko bleaching earth that is fit for purpose.

ENVIRONMENT FRIENDLY

- WE ARE COMMITTED TO KEEP OUR ENVIRONMENT CLEAN, SAFE AND HEALTHY.

- WE PROMOTE GREATER ENVIRONMENTAL AWARENESS IN OUR DAILY ACTIVITIES.

- PRESERVATION OF THE ENVIRONMENT IS THE RESPONSIBILITY OF EVERY EMPLOYEE.

- WE ARE COMMITTED TO TAKE GREAT CARE OF NATURE FOR THE WELL-BEING OF THE WORLD.

QUALITY MANAGEMENT

The Group adheres faithfully to strict quality controls reinforced by the awareness that a substantial portion of its products are used in the refining of oils and fats for human consumption.

Quality control measures, beginning from the extraction of raw materials up to the delivery of the finished products to customers, are implemented and monitored closely by the Group’s Product Assurance Team.

Testing is carried out by the Group’s in-house laboratories on every batch produced for bleaching performance, speed of filtration, residual acidity, moisture content, apparent density and particle size. Samples are also regularly sent out to independent laboratories to verify the accuracy of in-house tests.

External testing is carried out to determine the dioxin and dioxin like PCBs, non-dioxin like PCBs, Lead, Cadmium, Mercury and Arsenic content to comply with the European Union FEDIOL code of practice for the purchase of fresh bleaching earth for oil refining.

COST EFFICIENT

Our customers expect smooth refining operations at the lowest total refining costs when using Taiko bleaching earth. By listening and working closely with our customers, we have managed to consistently deliver this expectation to our customers. Through product research and development, customers using Taiko bleaching earth are enjoying longer filter cycles, lower utilities consumption, lower total refining losses, less maintenance downtimes and improved utilization of resources. Growing up in the highly efficient and competitive palm oil industry has made us understand and appreciate the true meaning of total value.

COMPLIANCE

Taiko is a registered trademark belonging to the Taiko Group and the brand name of the Group’s range of bleaching earth. Registration and/or usage of the trademark / brand name by other parties in any form or manner whatsoever is strictly prohibited unless specifically approved in writing by the Group.

CONTACT US

[199701013604 (429100-K)]

B2-05-01, Block B2, Meritus @ OASIS Corporate Park,

No. 2, Jalan PJU 1A/2, Ara Damansara,

47301 Petaling Jaya,

Selangor Darul Ehsan,

Malaysia.

Tel: +60 3 7660 7716 / +60 3 7660 9913